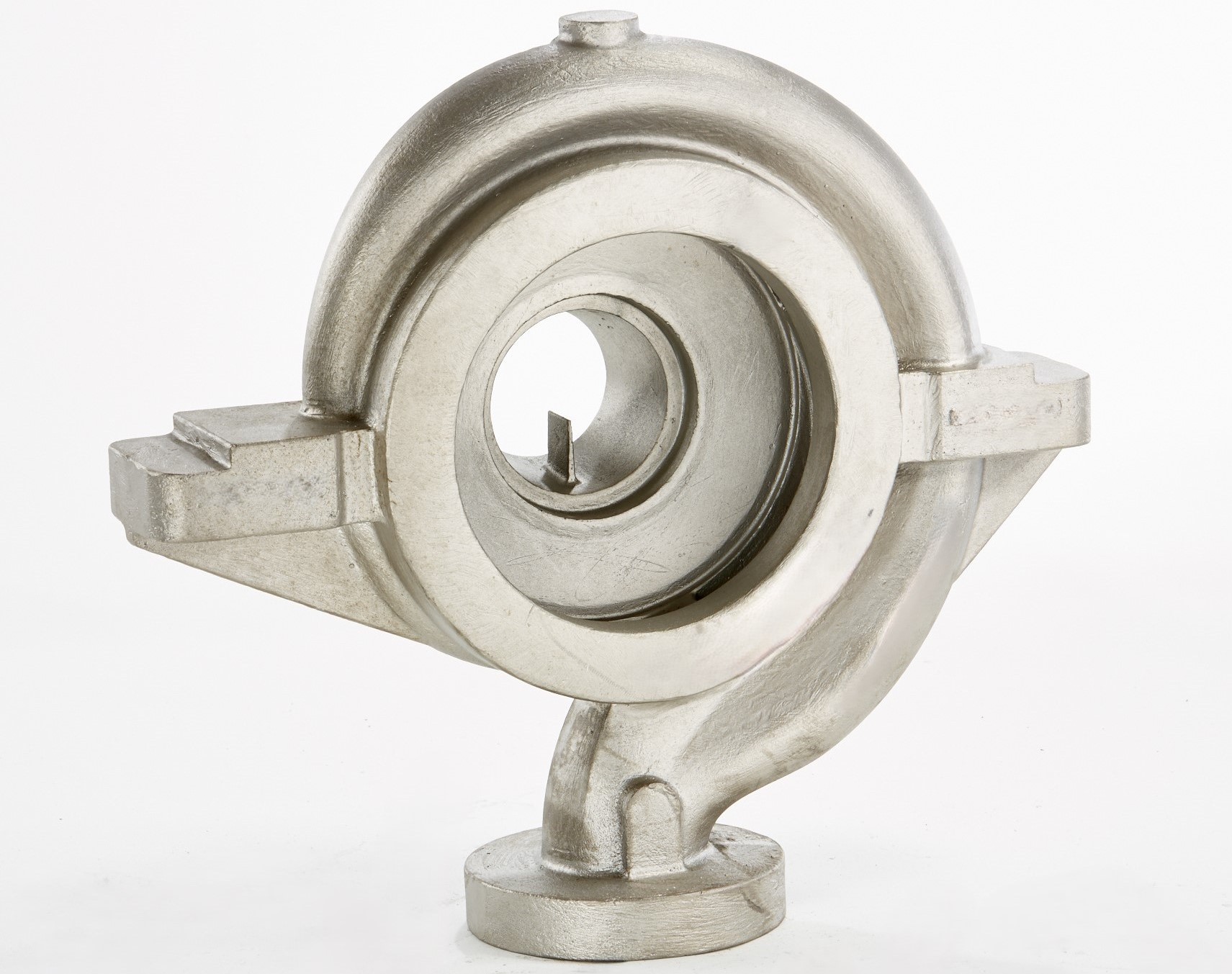

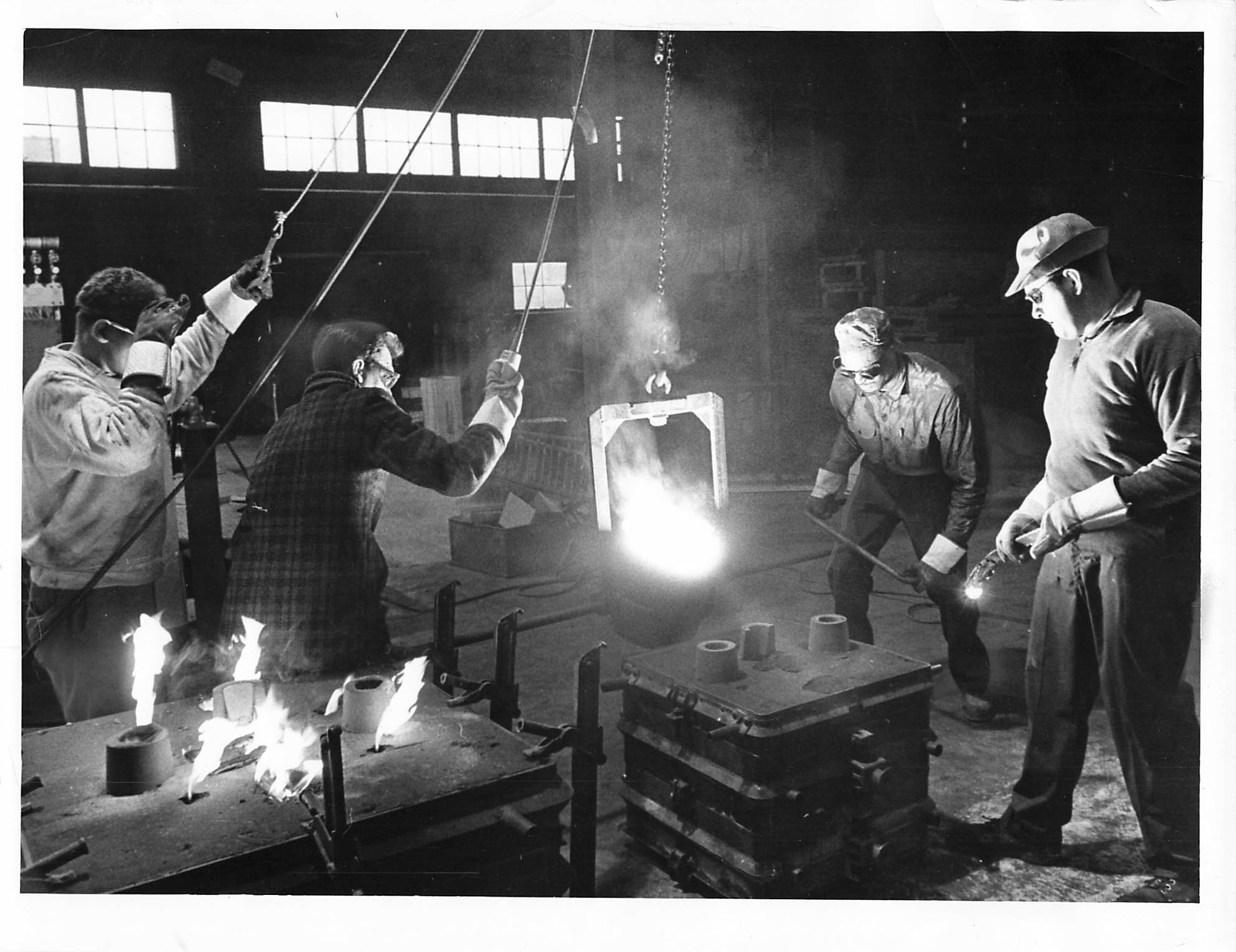

“World-class castings delivered” has been our commitment to customers for more than 50 years. A full-service sand casting manufacturer with single-source accountability for the entire casting process – from pattern to finish – Badger Alloys can meet your needs for simple to heavily cored, complex sand castings.

Our full-service sand casting manufacturing campus includes a foundry, machine shop, pattern facility, engineering team, and rapid response technologies. This on-site collaboration throughout the entire process ensures you the highest quality sand castings.

Equipped to meet your demands for castings from 10 – 4000+ pounds…in 200+ alloys.

Read More

Go from CAD to finished casting in expeditied timelines with our robotic patternless molding, 3D-printing and other additive/subtractive processes.

Read More

Skilled pattern makers create custom wood, polyurethane or metal patterns to your specifications.

Read More

Cutting-edge equipment and certified machinists meet your tightest tolerance requirements for keyway cutting, milling, dynamic balancing, and turning up to 10,000 lbs.

Read More

Our team works collaboratively with customers, foundry and pattern makers to achieve your desired casting result through reverse engineering, solidification analysis, 3D scanning, etc.

Read MoreUse our interactive tool to compare properties and find your ideal material.

Important information on castings, industry trends and what’s happening at Badger Alloys.

Valued Customers and Business Partners, It is with great pride that Badger Alloys celebrates its 60th year in business. As we celebrate this milestone, we recognize and express our heartfelt gratitude for your continued partnership and trust in us. Over…

A critical step in a casting’s journey through a foundry Sand Casting Shakeout, Cutoff, and Cleaning is a critical step The shakeout, cutoff and cleaning process in metal casting is a major intermediate step in preparing a casting for final…

Testing in sand casting is about predictability, performance, safety, and meeting design specifications and requirements Foundry melt labs conduct a range of tests to ensure the quality, structural integrity, and performance of cast components and the materials used in the…